Tradebe Inutec provides a fully integrated Waste Management Service comprising the ability to clearly articulate the customer technical challenge, identify the most appropriate solution including relevant Safey, Environmental and Transport Authorisations and the ultimate disposal of the Processed Waste.

Title to the Waste can be taken by Inutec at any stage in this process. This service can be delivered through processing of waste at Inutecs licensed site or through deployment and operation of mobile or bespoke waste handling equipment at the customers facilities.

Tradebe Inutec provides the UK nuclear industry with a proven and comprehensive LLW and higher activity waste treatment, processing, recycling and disposal service. Our customers, who have Radioactive Substances Act authorisations that include transfer of waste to Inutec, include Sellafield Limited, RSRL, Magnox, BEGL, AWE, MoD, GE Healthcare and Babcock Marine Services. Tradebe Inutec has been providing a LLW service for over 20 years. In addition, Tradebe Inutec offers a bespoke waste collection, processing and disposal service for users of small amounts of radioactive material such as hospitals, universities, schools, industrial research centres, museums and other establishments, where the amount of waste generated is insufficient to warrant dedicated waste conditioning facilities on the users own site.

Tradebe Inutec is regulated under the Environmental Permitting Regulations 2010 for solid, liquid and gaseous discharges from our facilities in Dorset, enabling us to process, condition and dispose of customer wastes and any resulting secondary wastes under our own authorised routes as well as those of our customers. These authorised routes cover the full spectrum of radioactive waste, encompassing ‘free release’ / exempt material through very low level waste (VLLW) and Low Level Waste (LLW) to higher activity wastes.

Tradebe Inutec uses a variety of waste conditioning processes, including size reduction, metal decontamination, drying, supercompaction, cement encapsulation, or a combination thereof as appropriate. The processing techniques are selected by appropriate best practicable environmental options (BPEO) and best practicable means (BPM) assessment. One of the primary aims is to minimise the volume of waste for disposal, whilst ensuring that the wasteform produced will minimise the release of any hazardous components, thus ensuring that the conditioned wasteform complies with the conditions for acceptance for disposal.

Tradebe Inutec’s medium/high active laboratories are a purpose-designed facility, extremely flexible and can be readily tailored to fit customer requirements. Facilities and operations include:

- Gloveboxes for alpha work; including corrosion studies

- Shielded gloveboxes for higher activity studies

- Characterisation and analysis of alpha material

- Waste characterisation and analysis

- Preparation of active materials for examination by various analytical methods in this and other facilities

- Small scale bench and loop experiments supporting decontamination reagent development studies

- Analysis of active materials using scanning electron microscopy (SEM) / energy dispersive spectroscopy (EDS), atomic absoption (AA) and inductively coupled plasma mass spectrometer (ICPMS)

- Analytical and radiochemical analysis of samples

- Chemical research experiments

- Storage of radioactive and nuclear materials

- Microstructural analysis using x-ray photoelectron spectroscopy (XPS) /secondary ion mass spectroscopy (SIMS), x-ray diffraction (XRD) and SEM / EDS

The laboratories form a key component of the integrated radioactive waste management service offered by Tradebe Inutec.

Radiological areas and radioactive inventories

The Winfrith medium/high active laboratories comprise three areas:

- A Category 3 Facility designated as Controlled with Contamination Moderate/Radiation Moderate

- Radioactive Materials Store; designated as Controlled with Radiation High

- The Microstructural Laboratory; designated as Supervised

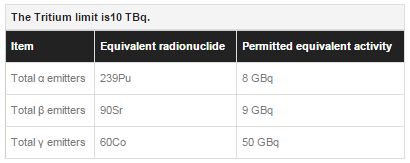

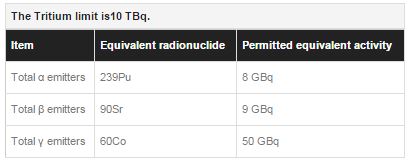

A wide range of different radionuclides can be received. In order to control the total inventory, all material received into the building is assigned equivalent activities of ‘standard’ radionuclides by using inhalation or dose rate equivalence; 239Pu for alpha emitters, 90Sr for beta emitters and 60Co for gamma emitters. Material is acceptable for receipt if the sum of equivalent radionuclide activities for each category remain below the facility safety case permitted limits. The permitted limits are:

Tradebe Inutec has a new plant for immobilising higher radiation alpha active wastes. The waste is emptied out of its transport packages and grouted into product drums for disposal.

The plant has a number of features that enable operations to be carried out safely and reliably:

- remote handling of the packages and waste emptying process

- shielding around all the plant

- high-integrity containment systems

- ventilation extract treatment systems, so that airborne discharges of radioactivity and chemicals to the environment are negligible

- state-of-the-art control systems and camera viewing systems.

These features are shown in the photographs of the plant for the various stages of the process. The plant is currently being used to remove thoria waste from steel drums and to mix it with cement grout in ‘lost paddle’ product drums.

Tradebe Inutec, through its Transport Projects Team has over forty years experience in maintaining and operating packages used for the transportation of radioactive materials both within the UK and overseas. Tradebe Inutec provides a fully proven comprehensive packaging and consultancy service available to meet all of the requirements for organisations involved in the transport of radioactive materials worldwide.

Packaging

Tradebe Inutec operates and maintains it’s own fleet of packages. This fleet of packages ranges from simple IP1 & IP2 types, through Type A disposable packages, up to Type B flasks for the transportation of irradiated fuels and high activity sources. If a customer’s specific requirement cannot be met by any of our current flasks, we will seek to modify an existing package certificate or design, for the most cost- effective solution to the customer. An additional field of expertise involves instruction and assistance with package handling, package loading and the leak testing of packages used in Radioactive material shipments.

Transactive

In addition to the packaging types described above, Inutec has commissioned the Transactive-20 container. This container is used to transport large quantities of intermediate level waste. The package is approved to IAEA Type B(U)F standards and could potentially be licensed to carry a wide variety of payloads.

Transportation

The transportation of radioactive materials involves careful planning and consultation with all of the sites and agencies involved, to ensure full compliance with national and international legislation. Tradebe Inutec have successfully completed many varied and complex projects worldwide, utilising most aspects of the transport spectrum: road, air and sea.

Maintenance

A comprehensive maintenance service, including completion of ‘Turn-Round Maintenance’ and ‘Annual/Periodic Maintenance’ either on customer’s own sites or in Inutec’s own dedicated maintenance facility.

Consultancy

The combination of expertise and relevant experience ensures that Inutec personnel maintain an accurate working knowledge of all the regulations associated with the safe transportation of radioactive materials and that all transport operations operate within national and international regulations and to ISO9001:2000. With their unrivalled expertise in such a wide range of areas, Tradebe Inutec are able to provide the customer with a comprehensive Consultancy Services on radioactive materials transport and packaging solutions.

Tradebe Inutec’s Transportation & Packaging experience includes:

- Import and Export of all types of radioactive materials.

- Radioactive material transport consultancy and option studies.

- Safety documentation including: risk and hazard assessments and contingency planning.

- Packaging maintenance, care and custody.

- Collaboration with various facilities worldwide including BNG Sellafield/Windscale; NRI Rez, Czech Republic; VTT, Finland; MHI, Japan; Halden, Norway

Transport containers for radioactive materials are tested to demonstrate compliance with national and international standards. At Winfrith, there are drop-test cranes and targets (up to 700 tonne). The protocols employed are normally IAEA Safety Series 6, or ST1 for transport containers, although tests have also been conducted to US DoE 10CFR71. Containers that are to be used entirely within a nuclear facility are tested to ensure compliance with relevant safety cases. The impact facilities have also been extensively used for investigation of the performance of components of transport packages, such as the shock absorbers, or the intended payloads.

Drop Test Facilities

The principal facility used for drop tests comprises a 150 tonne crawler crane and a 700 tonne concrete target. The crane is capable of dropping a 90 tonne load from a height of 30 m, or a 50 tonne load from a hook height of 55 m. The target consists of a buried reinforced concrete block, with the upper 6 m square steel face located 0.5 m above ground level. Tests have been conducted on a number of different types of containers and packing (e.g. flasks, drums, ISOs), some with unusual configurations.

Indoor facilities, used for the testing of smaller packages or scale models in conditions independent of the weather, have a maximum drop height of 10 m. Tests are conducted on packages weighing from between 2 and 50 kg.

Instrumentation routinely employed in impact testing includes high-speed video or cine cameras, accelerometers, strain gauges and pressure transducers. Data are collected using transient recorders, operating at sample rates of up to 300,000 per second. A large co-ordinate measuring machine is available for metrology. Techniques for leak testing of containers range from soap bubble testing to gas mass spectrometry.

Tradebe Inutec can also provide expert advice on drop testing and impact analysis as well as lift preperation and planning to support the Drop Test Facility.

CEMENT WASTEFORM FORMULATION DEVELOPMENT

Tradebe Inutec has, over a period of many years, been the main contractor to a number of the UK’s principal nuclear organisations for the development of formulations for cementation of Intermediate Level Wastes arising from fuel reprocessing and power station operations. This includes materials such as fuel element debris, ion exchange resins, borated wastes and effluent treatment plant sludges. The results and experience gained from these development programmes has been used to demonstrate the acceptability of the developed formulations in support of the strategy for encapsulation and disposal of the radioactive waste arisings.

The formulation development work will typically be carried out at small scale using inactive simulants, backed up by large-scale inactive tests and if practical, small-scale active tests as well. A key objective is to define a process envelope sufficient to cater for the variations in waste feed composition and inactive material delivery likely to be encountered on a fully operational plant. Familiarity with Nirex requirements allows the targeting of programmes and our extensive experience enables an informed judgement of the starting point. A full range of performance evaluation tests, such as compressive strength measurement, dimensional stability measurement, leach and immersion testing, is used to support the formulation work.

We are also able to provide this service for a similar wide range of LLW based on our familiarity with Drigg disposal requirements. For LLW we are able to combine the formulation development with actual operations, using our LLW cement plant sited at Winfrith, to provide a turnkey service which results in the disposal of cemented waste to BNGLLWR site in Cumbria.

ANALYTICAL CHEMISTRY

Tradebe Inutec provides a comprehensive analytical chemistry service encompassing radionuclide, chemical and physical analysis. Inutec has extensive experience in the analysis of a diverse range of materials, from seafood, soil, waters, liquid effluents, “soft” wastes, to the characterisation of the nuclear inventory of fuel pond-skip corrosion scales. Particular expertise has been developed for the separation and determination of pure beta emitting nuclides.

Tradebe Inutec offers a comprehensive facility for the analysis of radionuclides from environmental levels to those encountered in operational and decommissioning nuclear wastes.

Tradebe Inutec’s specialist radionuclide analysis capabilities include:

- Rapid Screening Techniques

- Gross Alpha, Beta and Gamma activity analysis

- High Resolution Gamma Spectrometry

- Alpha Spectrometry

- Liquid Scintillation Counting

- Inductively Coupled Plasma Mass Spectrometry

- Specific Radionuclide Analysis

The radionuclide analysis area is supported by chemical analysis service which has extensive experience in the chemical analysis of biological, environmental and radioactive samples.

A range of modern and traditional methods for the measurement of organic, inorganic and radioactive species are routinely employed including:

- Atomic Adsorption Spectroscopy

- Inductively Coupled Optical Emission Spectroscopy (ICPOES)

- Inductively Coupled Mass Spectrometry (ICPMS)

- Dionex Chromatography

- Gas Chromatography

- UV/Visible Spectrometry

- Colorimetry

A microstructural analysis service is also provided using SEM, SIMS and XRD techniques.

A dedicated facility has also been developed for the analysis of tritium and carbon 14 in nuclear site operational and decommissioning wastes using a combustion technique. This includes a major facility for the analysis of wastes contaminated with beryllium - specifically developed to analyse wastes generated by the Joint European Torus facility at Culham. Over the past few years, considerable expertise has been developed in the analysis of a wide variety of materials using this technique. These include:

- Soft wastes (e.g. rubbers, plastics, paints, cellulose materials)

- Metals

- Oils

- Wood

- Environmental materials (eg. soils, vegetation, biota)

- Resins

- Reactor graphite

- Beryllium contaminated material

Tradebe Inutec is committed to the implementation of effective and efficient quality management systems consistent with the requirements of BS EN ISO9001:2008.

SUPERCOMPACTION OF ASBESTOS LLW

Due to the high costs of LLW disposal, many waste generating companies seek to reduce their costs through volume reduction of their wastes prior to disposal. Previously in the UK, volume reduction of asbestos wastes has not been feasible. Tradebe Inutec operates a mobile supercompaction operation, processing waste for external clients and this service has now been extended to include asbestos wastes. Waste can either be transported to Tradebe Inutec’s Winfrith site base for treatment, or the plant can be set up and operated on the client's site.

Tradebe Inutec operates a mobile asbestos LLW supercompaction service, based at its Winfrith site. Asbestos enclosures are set up around the mobile plant, and a comprehensive monitoring programme is carried out. 8,000 drums have been processed to date. For UK waste the compacted drums or pucks are monitored, measured, double-wrapped and loaded into half height ISO transport containers.

Tradebe Inutec obtains all the necessary authorisations and transports the final waste container to the LLWR site in Cumbria for disposal.

Recent super compaction campaigns have achieved packing of in excess of 300 pucks per a half-height ISO container the average being >250. The average volume reduction factor for the asbestos drums was nearly 8.

CRUSHING AND SUPERCOMPACTION OF HEPA FILTERS

Due to the high costs of LLW disposal, many waste generating companies seek to reduce their costs through volume reduction of their wastes prior to disposal. The issue of escalating costs and waste volume reduction is common throughout the world. Inutec operates a mobile supercompaction operation, processing waste for external clients, and the scope of this service has now been extended to include treatment of square HEPA filters. Waste can either be transported to the Winfrith base for treatment, or the plant can be set up and operated on the client's site.

Tradebe Inutec operates a mobile asbestos LLW supercompaction service, based at its Winfrith site. Asbestos enclosures are set up around the mobile plant, and a comprehensive monitoring programme is carried out. 8,000 drums have been processed to date. For UK waste the compacted drums or pucks are monitored, measured, double-wrapped and loaded into half height ISO transport containers.

Tradebe Inutec obtain all the necessary authorisations and transport the final waste container to the LLWR site in Cumbria for disposal.

Recent super compaction campaigns have achieved packing of in excess of 300 pucks per a half-height ISO container the average being >250. The average volume reduction factor for the asbestos drums was nearly 8.

SUPERCOMPACTION OF LLW

Due to the high costs of low level radioactive waste (LLW) disposal, many waste generating companies seek to reduce their costs through volume reduction of their wastes prior to disposal. In addition to this, it is now a requirement for LLW disposal at the BNGLLWR site in Cumbria that compactable wastes are supercompacted, wherever possible. Tradebe Inutec operates a mobile supercompaction operation, based at its Winfrith site, processing waste for external clients. Waste can either be transported to Winfrith for treatment, or the plant can be set up and operated on the client's site, as has happened in the UK and overseas for French, Belgian, Czech and Swiss wastes.

Tradebe Inutec operates a mobile supercompaction plant that is designed to process standard 200 litre waste drums. It has a maximum operating capacity of 2000 tonnes and a cycle time of approximately 4 minutes. The routine scope of supply includes drum and supercompacted puck handling equipment, puck measuring equipment, activity-in-air monitoring equipment and onward product transport.

To date over 90,000 drums have been processed. For UK waste, the compacted drums, or pucks, are monitored, measured, wrapped if required, and loaded into half height ISO transport containers (HISOs). For Winfrith operations, Inutec obtains all the necessary authorisations and transports the final waste container to the LLWR site in Cumbria for disposal.

Over the course of these campaigns, the average number of pucks loaded into an HISO container has been in excess of 190. The average volume reduction factor for the drums is in the region of 5.

Tradebe Inutec has extensive experience in a range of different tritium handling and processing operations. This experience includes the following

- Assessment of tritium content of tritiated materials

- Design and development of tritium handling facilities

- Operation of detritiation plant

- Packaging and disposal of tritiated wastes

Tradebe Inutec has extensive tritium capabilities at Winfrith. Importantly, in association with this, we have discharge authorisations for gaseous and liquid tritium from the Winfrith site. In support to this we are also able to offer our extensive expertise in safety and safety documentation for tritium work. This includes plant safety, commissioning and operations, analysis, designing and undertaking dedicated experiments and development, environmental impact assessment, discharge monitoring and discharge minimisation. We operate safe working practices for all our plant, and have specific procedures developed for tritium work.

Tradebe Inutec has in-house capabilities for tritium measurement by scintillation counting of liquid samples, on-line ionisation chamber measurement of gas and airborne tritium, radiographical measurement of tritium distribution over surfaces, mass spectrometry, and dedicated in-plant equipment associated with tritium recycling.

Tradebe Inutec has extensive experience in a range of different tritium operations. This experience includes the following:

- Operation of detritiation plant

- Assessment of tritium content of tritiated materials

- Monitoring and assessment of tritium in air concentrations

- Design and development of tritium handling facilities

- Packaging and disposal of tritiated wastes

HG DECONTAMINATION

Tradebe Inutec is a leading provider of independent radioactive waste management services to the UK and overseas nuclear market.

Few companies in the UK can offer similar depth and breadth of resource and expertise and indeed, no single company offers the same comprehensive radioactive waste management capabilities.

Tradebe Inutec is able to provide a full range of services for radioactive waste management and decommissioning (both LLW and ILW), including:

- Waste management assessments and consultancy studies

- Waste sampling and characterisation

- Advanced waste treatment processes

- Recycling, recovery and recategorisation (e.g.detritiation)

- Waste packaging and immobilisation

- Impact and fire testing of transport packages

- Radioactive materials transport

- Analytical and radiochemistry

- High temperature chemistry

- Waste management plant optimisation, design review and validation

- Tradebe Inutec is able to provide a highly specialised and fully integrated approach to delivering solutions across the waste management cycle.

Tradebe Inutec has wide experience of the UK regulatory requirements for both plant and processes, including the Nirex LoC, specifications and disposal concept, the safety requirements for a nuclear licensed site and environmental regulation and legislation.

The business has longstanding, well-established relationships with all of the leading operators in the UK nuclear industry as well as many overseas organisations spanning over 25 years.

Tradebe Inutec Winfrith site is unique in terms of both its technology, facilities and its radioactive discharge authorisations.

MERCURY DECONTAMINATION

Tradebe Inutec has developed a mercury decontamination process that has been used to decontaminate elemental mercury contaminated with alpha and beta emitting radionuclides.

The process comprises 3 stages. These are:

- Pin-hole filtration to remove solid contaminants;

- Acid washing of extended duration to remove soluble contaminants;

- Mercury distillation, to be used as a final polishing step.

For any new mercury waste stream Inutec undertakes evaluation trials to ensure the process is both effective and optimised. As an example more than one acid wash maybe required to remove all the soluble contamination.

Tradebe Inutec has fully equipped radiochemical analysis facilities that allow the mercury to be characterised at all stages of the decontamination process.

Upon decontamination Tradebe Inutec transfers the cleaned mercury to a commercial mercury recycling company, an EA approved disposal route . Secondary waste, such as contaminated acid wash liquor is processed and disposed of using Tradebe Inutec established disposal routes.

Track Record

Tradebe Inutec has decontaminated more than 4 tonnes of contaminated mercury. The most recent project being the decontamination and free release of 1.25 tonnes of mercury contaminated with tritium.

DRYING AND SUPERCOMPACTION OF WET LLW

LLW disposal facilities require wastes to be dry and high disposal costs mean that volume reduction of the wastes prior to disposal should be carried out wherever practical. These issues are generally common throughout the world. Tradebe Inutec provides a service for the drying and supercompaction of wet low level wastes, processing the material for external clients. Waste can either be transported to Inutec’s Winfrith site for treatment, or either or both of the two plants can be set up and operated on the client's site.

Tradebe Inutec has established a drying & supercompaction service, for the treatment of wet LLW. The drying units available can accommodate a variety of package configurations, whilst the supercompaction plant is designed to process standard 200 litre waste drums. Tradebe Inutec has access to a suite of drying units, with a maximum capacity of 30 off 200 litre waste drums; water contents well in excess of 50% w/w can be processed and the cycle time for a batch is 10-14 days. The supercompactor has a maximum operating force of 2000 tonnes. For UK waste, the drums are dried to less than 5% w/w water content, supercompacted, pucks monitored, measured, wrapped if required and loaded into half height ISO transport containers. Inutec obtains all the necessary authorisations and transports the final waste container to the LWR site in Cumbria for disposal.

This process for wet wastes produces a waste form acceptable for LLW disposal with overall volume reduction factors for the drums in the region of 4, compared to the volume increase provided by conventional cementation.

Tradebe Inutec’s medium/high active laboratories are a purpose-designed facility, extremely flexible and can be readily tailored to fit customer requirements. Facilities and operations include:

- Gloveboxes for alpha work; including corrosion studies

- Shielded gloveboxes for higher activity studies

- Characterisation and analysis of alpha material

- Waste characterisation and analysis

- Preparation of active materials for examination by various analytical methods in this and other facilities

- Small scale bench and loop experiments supporting decontamination reagent development studies

- Analysis of active materials using scanning electron microscopy (SEM) / energy dispersive spectroscopy (EDS), atomic absoption (AA) and inductively coupled plasma mass spectrometer (ICPMS)

- Analytical and radiochemical analysis of samples

- Chemical research experiments

- Storage of radioactive and nuclear materials

- Microstructural analysis using x-ray photoelectron spectroscopy (XPS) /secondary ion mass spectroscopy (SIMS), x-ray diffraction (XRD) and SEM / EDS

- The laboratories form a key component of the integrated radioactive waste management service offered by Tradebe Inutec.

Radiological areas and radioactive inventories

The Winfrith medium/high active laboratories comprise three areas:

- A Category 3 Facility designated as Controlled with Contamination Moderate/Radiation Moderate

- Radioactive Materials Store; designated as Controlled with Radiation High

- The Microstructural Laboratory; designated as Supervised

A wide range of different radionuclides can be received. In order to control the total inventory, all material received into the building is assigned equivalent activities of ‘standard’ radionuclides by using inhalation or dose rate equivalence; 239Pu for alpha emitters, 90Sr for beta emitters and 60Co for gamma emitters. Material is acceptable for receipt if the sum of equivalent radionuclide activities for each category remain below the facility safety case permitted limits. The permitted limits are: