Category

Health & SafetyCreation date

Eye Injuries in the workplace are very common. Keep your team safe by ensuring everyone is aware of Workplace Eye Safety Hazards and using Proper Eye Protection for the job.

The National Institute for Occupational Safety and Health NIOSH reports that every day about 2,000 U.S. workers sustain job-related eye injuries that require medical treatment.

However, safety experts and eye doctors believe the proper eye protection can lessen the severity or even prevent 90 percent of these eye injuries.

Chemicals or foreign objects in the eye and cuts or scrapes on the cornea are common eye injuries that occur at work. Other common eye injuries come from splashes with grease and oil, burns from steam, ultraviolet or infrared radiation exposure, and flying wood or metal chips.

Workers experience eye injuries on the job for two major reasons:

- They were not wearing eye protection.

- They were wearing the wrong kind of protection for the job.

A Bureau of Labor Statistics survey of workers who suffered eye injuries revealed that nearly three out of five were not wearing eye protection at the time of the accident. These workers most often reported that they believed protection was not required for the situation.

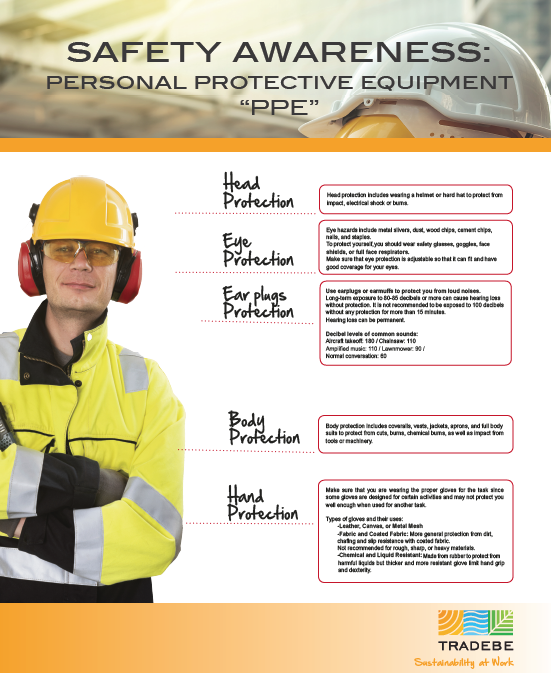

The Occupational Safety and Health Administration (OSHA) requires workers to use eye and face protection whenever there is a reasonable probability of injury that could be prevented by such equipment. Personal protective eyewear, such as goggles, face shields, safety glasses or full-face respirators must be used when an eye hazard exists. The necessary eye protection depends upon the type of hazard, the circumstances of exposure, other protective equipment used and individual vision needs.

What are a few potential eye hazards in your workplace?

Tradebe employs a wide range of personnel to manage an ever-growing assortment of reclamation, transportation and field service projects.

Types of hazards that would require eye protection include:

- Projectiles (dust, concrete, metal, wood and other particles)

- Chemicals (splashes and fumes)

- Radiation (especially visible light, ultraviolet radiation, heat or infrared radiation, and lasers)

- Bloodborne pathogens (hepatitis or HIV) from blood and body fluids

Think about your workplace as a whole - where is eye protection required and what potential eye hazards are present?

Job tasks with a high risk for eye injuries include:

- chemical handling

- chemical transfer

- tank cleaning

- mining

- equipment repair

- electrical work

- plumbing

- welding

- maintenance

- blasting

Some working conditions include multiple eye hazards. The proper eye protection takes all hazards into account.

The type of safety eye protection you should wear depends on the hazards in your workplace:

- If you are working in an area that has particles, flying objects or dust, you must at least wear safety glasses with side protection.

- If you are working with chemicals, you must wear goggles.

- If you are working with a potential splash hazard, you must wear a face shield.

- If you are working in a confined space, area with a potentially hazardous atmosphere or harmful vapors, you must wear a full-face respirator.

Know the requirements for your work environment.

Side shields placed on your conventional (dress) glasses do not provide enough protection to meet the OSHA requirement for many work environments.

Tradebe’s priority is Safety and the Protection of People and the Environment. Wherever possible, our SHEQ team is focused on greatly reducing the probability of workplace eye-injures by:

- Educating employees, contractors and visitors on workplace hazards

- Conducting an eye hazard assessments of the workplace

- Removing or reducing eye hazards where possible

- Providing appropriate safety eyewear to employees

- Empowering employees by improving workplace safety

What should be done in an eye emergency?

Seek medical attention as soon as possible following an injury, particularly if you have pain in the eye, blurred vision or loss of any vision. Alert Environmental Health & Safety of any workplace eye-injuries or incidents. Several simple first aid steps can and should be taken until medical assistance is obtained.

First aid for chemicals in the eye:

- Immediately flush the eye with water for at least 15 minutes. Place the eye under a faucet or shower, use a garden hose, or pour water into the eye from a clean container.

- If you are wearing contact lenses, immediately remove them before flushing the eye.

- Do not try to neutralize the chemical with other substances.

- Do not bandage the eye.

- Seek immediate medical attention after flushing.

First aid for particles in the eye:

- Do not rub the eye.

- Try to let your tears wash the speck out, or irrigate the eye with an artificial tear solution.

- Try lifting the upper eyelid outward and down over the lower eyelid to remove the particle.

- If the particle does not wash out, keep the eye closed, bandage it lightly and seek medical care.

- Some particles, particularly metallic ones, can cause rusting spots on the eye if left untreated for several days. If you are unsure if the object is gone, do not delay medical care.

First aid for blows to the eye:

- Gently apply a cold compress without putting pressure on the eye. Crushed ice in a plastic bag can be placed gently on the injured eye to reduce pain and swelling.

- In cases of severe pain or reduced vision, seek immediate medical care.

First aid for cuts and punctures to the eye or eyelid:

- Do not wash out the eye.

- Do not attempt to remove an object that is stuck in the eye.

- Cover the eye with a rigid shield, like the bottom half of a paper cup.

- Seek immediate medical care.

10 Important Eye Safety Tips

- Be aware of workplace eye safety hazards

- Select the proper eye protection for the job

- Encourage co-workers to adopt and adhere to EHS safety culture

- Use company-provided eye protection whenever the potential eye safety hazards exist

- Safety eyewear must have “ANSI Z87” clearly marked on all glasses or goggles and should always be worn whenever eye hazards are present.

- Keep your safety eyewear in good condition and have it replaced if it becomes damaged.

- Eliminate hazards before starting work by using machine guarding or other engineering controls.

- Alert EHS or Supervisors immediately if safety hazards are discovered.

- Be aware of eyewash and first aid locations in your workplace

- Seek medical attention as soon as possible if experiencing an eye injury

Various levels of PPE are an important and necessary part of our daily routine at Tradebe. Need help with your Environmental Health and Safety Plan? Contact us now and let us put our expertise to work for you!

“Be Safe - Work Safe. Safety is No Accident!”

William Martin-Black, Health & Safety Specialist, Tradebe USA

#HealthandSafetyPlan #WorkplaceEyeSafetyHazards #ProperEyeProtection #EyeInjury #PersonalProtectiveEquipment #BeSafeWorkSafe #SafetyisNoAccident

Resources:

https://www.cdc.gov/niosh/topics/eye/resources.html

https://www.osha.gov/laws-regs/regulations/standardnumber/1910/1910.133

https://www.aoa.org/patients-and-public/caring-for-your-vision/protecting-your-vision

https://www.allaboutvision.com/safety/

Subscribe to Tradebe Safety Blog, news and more...

Related articles and information:

- Tradebe blog article “Avoiding Static Electric Shock Hazards”

- Tradebe blog article "Understanding Proper PPE"

__________________________________________

At Tradebe, our priorities are safety and the protection of people and the environment. Safety is a common “water cooler” topic here at Tradebe where a culture of Safety is Top Priority. If Safety is important to your business, catch the latest buzz: Subscribe Now…